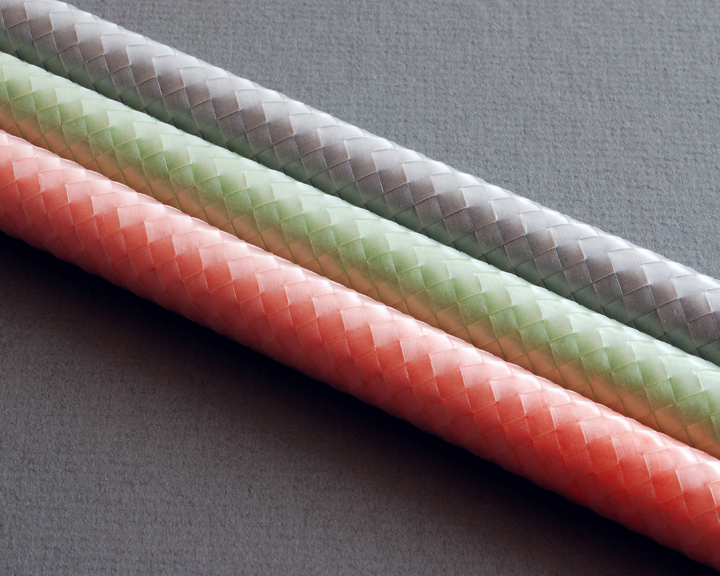

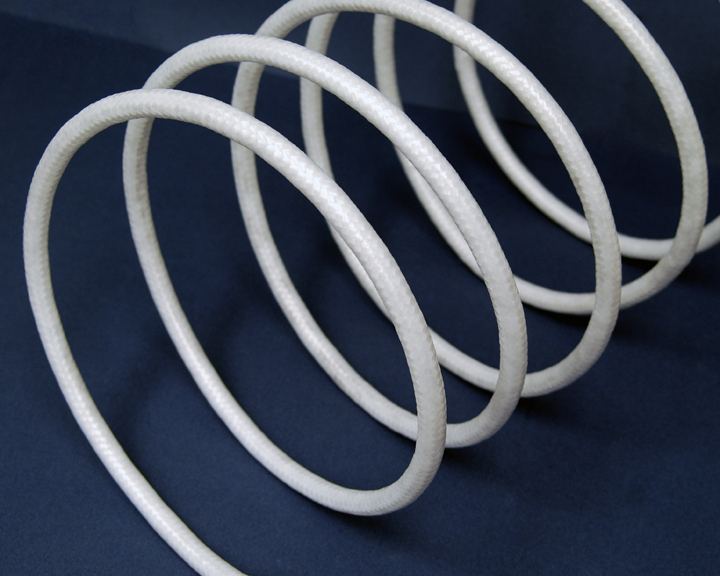

Braiding has long been used for making cordage products. When using high strength UHMWPE fibers, such products can exhibit high tensile strength even surpassing that of steel. By incorporating UHMWPE tapes in their braided construction, the cordage products can include additional features such as superior abrasion resistance, controlled flexibility or stiffness, and reduced recoil upon breakage.

Project Examples:

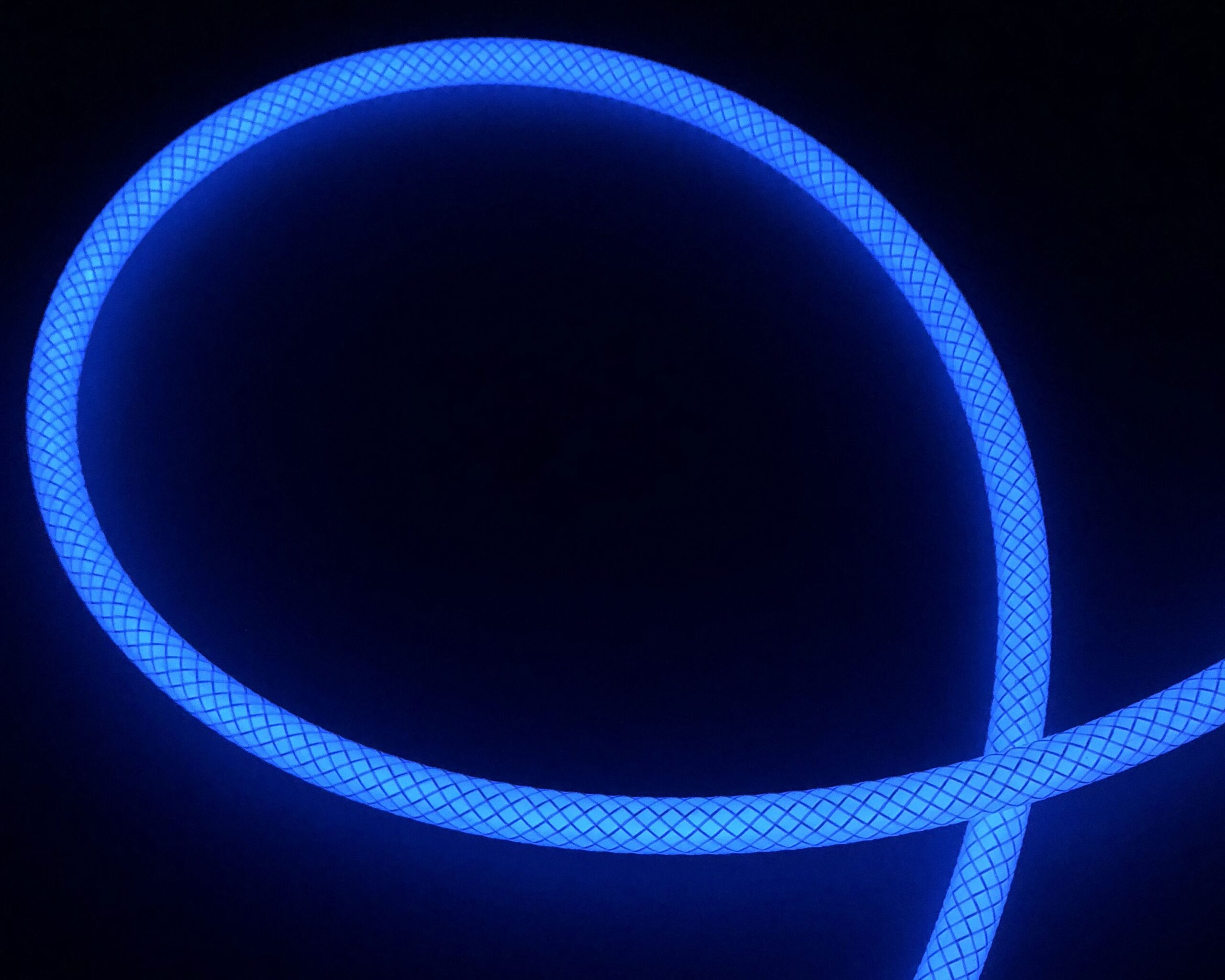

Architectural Installation: Innovation with Light

Our team was tasked with developing novel polymer cable constructions for serving as elements of an architectural installation. Required functional and aesthetic criteria included suitable materials to achieve the visual effect desired by the client, the incorporation of lighting components such as fiber optics, load-bearing capacity and cable termination and anchoring hardware.

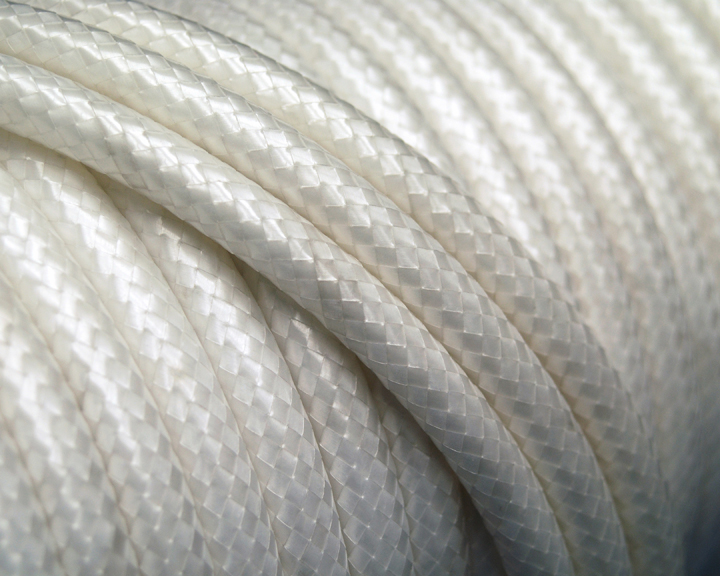

Building the Safest Rope

In its quest to build the safest rope, our team conducted field tests with long lengths of ropes having a novel construction that showed a significant reduction in recoil speed and a different energy dissipation profile in comparison to conventional ropes. The different energy dissipation profile associating with its unique braided construction provides an innovative approach for reducing recoil upon rope breakage and improving safety.

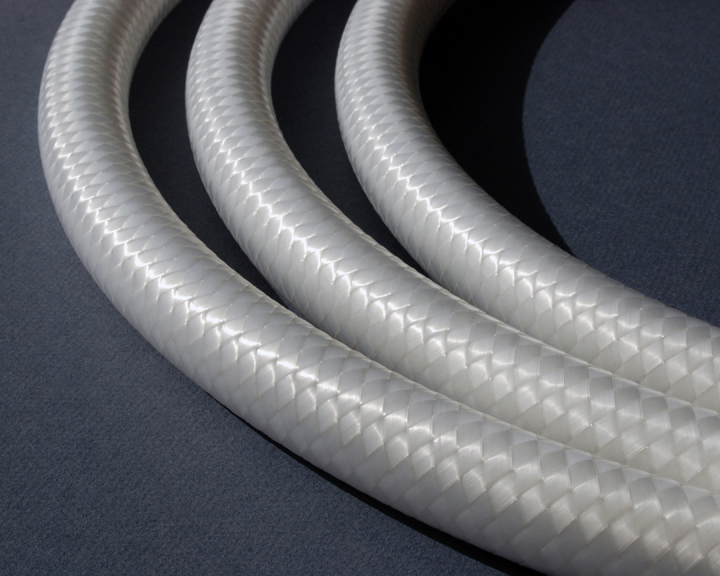

Sailboat Racing

Our team developed a novel lightweight polymer cable for sailboat racing performance that was designed to combine the cable-like properties typically associated with metal cables, but with the benefits of synthetic polymer rigging, featuring light weight, reduced diameter, low elongation, smooth profile, easy installation, outstanding chafe resistance and UV protection. This novel cable was used as a backstay on a racing sailboat competing in international events and finishing on the podium.